Products

Roll Sheet Forming Technologies

Corner Profile Production Line | Cemax Engineering

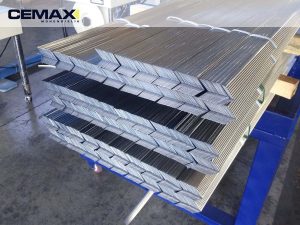

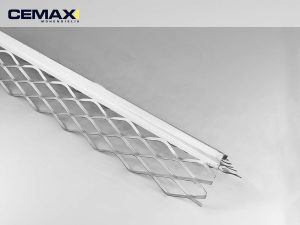

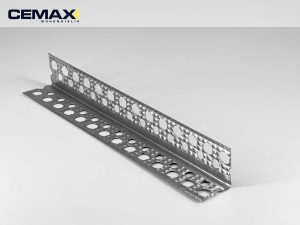

These are the lines that produce profiles made of galvanized sheet, which are used to protect the outer corners against impacts in gypsum board systems and to create a smooth corner detail.

- Easy setup

- Affordable Cost

- Durable Material

Corner Profile Production Line

Production Line Code | Product Description | Profile | Number of Stations | Technicial Specifications | Thickness of the Product to be Drawn | Production Line Speed |

CMX-KPH1-PLUS | Plaster Corner Profile Production Line | Plaster Corner Profile | 6 Stations | Decoiler-Tunnel-Eccentric Press-Tunnel-Rollform-Cut to Length-Stacking Table | 0.3 mm- 0.5 mm | 30m/min-50m/min |

CMX-KPH2-PLUS | Plaster Corner Profile Production Line | Gypsum Corner Profile | 6 Stations | Decoiler-Tunnel-Eccentric Press-Tunnel-Rollform-Cut to Length-Stacking Table | 0.3 mm- 0.5 mm | 30m/min-50m/min |

CMX-KPH3-PLUS | Plaster Corner Profile Production Line | Gauge Profile | 8 Stations | Decoiler-Tunnel-Eccentric Press-Tunnel-Rollform-Cut to Length-Stacking Table | 0.3 mm- 0.5 mm | 30m/min-50m/min |

CMX-KPH4-PLUS | Gypsum Corner Profile Production Line | Gypsum Corner Profile | 6 Stations | Decoiler-Tunnel-Eccentric Press-Tunnel-Rollform-Cut to Length-Stacking Table | 0.3 mm- 0.5 mm | 85m/min |

CMX-KPH5-PLUS | Gypsum Corner Profile Production Line | Gauge Profile | 6 Stations | Decoiler-Tunnel-Eccentric Press-Tunnel-Rollform-Cut to Length-Stacking Table | 0.3 mm- 0.5 mm | 85m/min |

Optional Equipment | ||||

Decoiler | Intermediate Tunnel | Pres | Rollform | Cutting Unit |

Number of Changeable Titles | Tunnel Width | Press Capacity | Number of Stations | Servo System |

Variable Weight Capacity | Tunnel Height | Servo Drive System | Cassette/Cassetteless System | Pneumatic System |

Changeable Roll Clamping System | Punching Unit | Angle Cutting – Cutting System With Waste | ||

Attachable Sheet Sliding System | ||||