Gypsum Board Profile Production Lines

In the construction sector, the demand and need for gypsum board is increasing day by day. Rapidly advancing technology, when combined with professional service, can produce high-quality and aesthetically pleasing results. Its ease of installation and subsequent use significantly reduces the need for manual labor. Among building materials, gypsum board is now one of the most favored materials. Closely related to gypsum board, the Gypsum Board Profile Production Line facilitates the production of many building materials and ensures fast results.

Gypsum board is manufactured according to specific standards. It enables the creation of ideal and practical equipment for the construction sector. Produced in various features and sizes, gypsum board has a durable structure against impacts, fire, moisture, and humidity. It can be shaped according to the area of use and the desired requirements. With its thermal and sound insulation properties, gypsum board can also be specially manufactured on request.

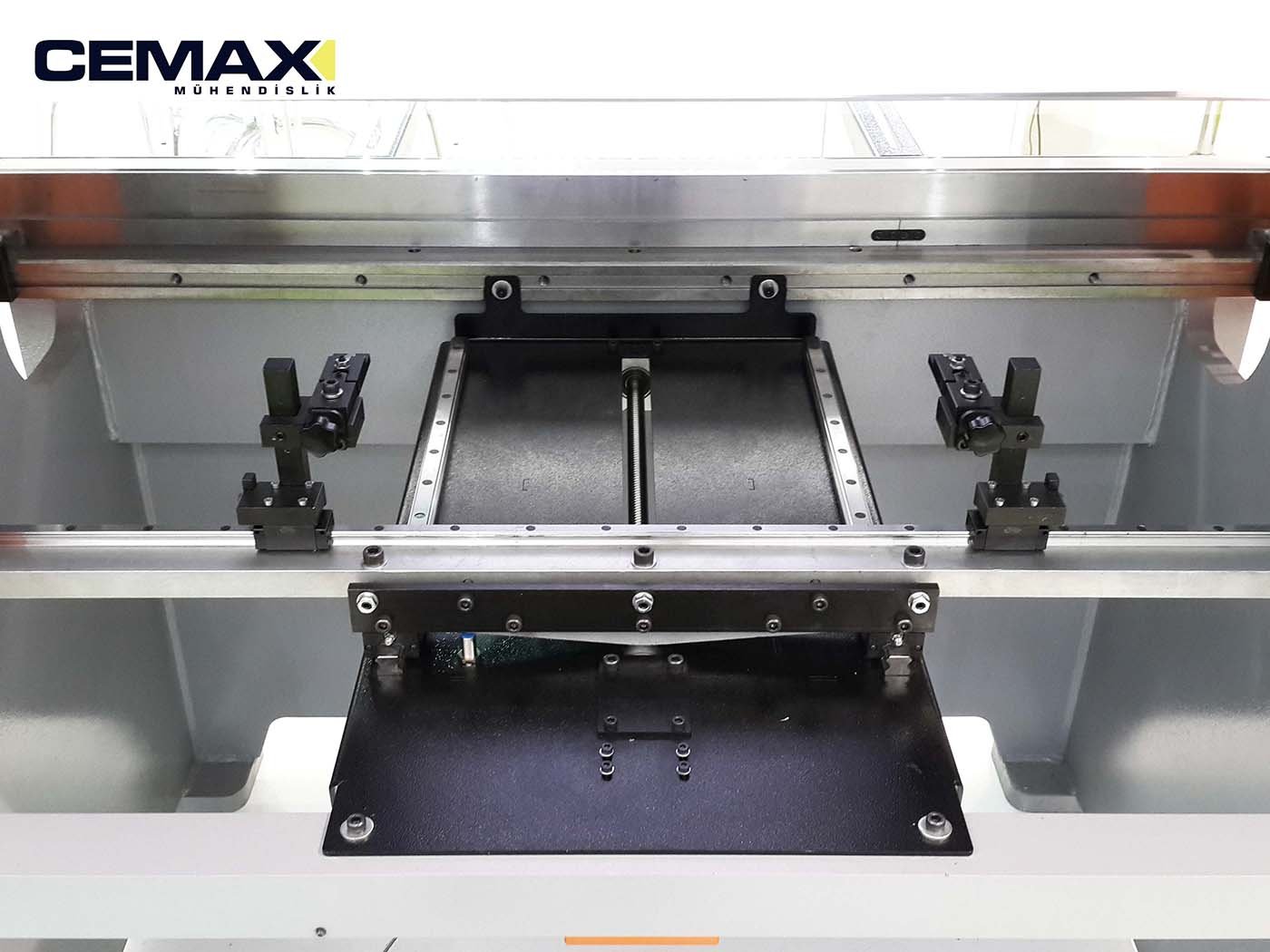

Gypsum Board Profile Lines are machines that can produce profiles in 14 different sizes with high speed and quality. The optional features of Cemax Engineering’s Gypsum Board Profile Production Line can be listed as follows:

- Cassette-type roll forming stations.

- Profile patterns based on customer samples.

- Punching unit.

- Production of PVC support sheets, etc., based on customer samples.

Its standard technical specifications are as follows:

- Production speed: 60 meters/min.

- Decoiler: 2000 kg coil sheet carrying capacity.

- Roll form: 12 stations.

- Automation: Schneider.

- Switchgear: Siemens, Moeller, Schneider brand.

- Flying shear: Servo motor driven.

- Profile discharge table: Pneumatic.

- Roller and mold rack: Stores rollers and molds for 24 stations.

Cemax Engineering integrates professional operations with quality, offering solutions tailored to the needs of the sector.

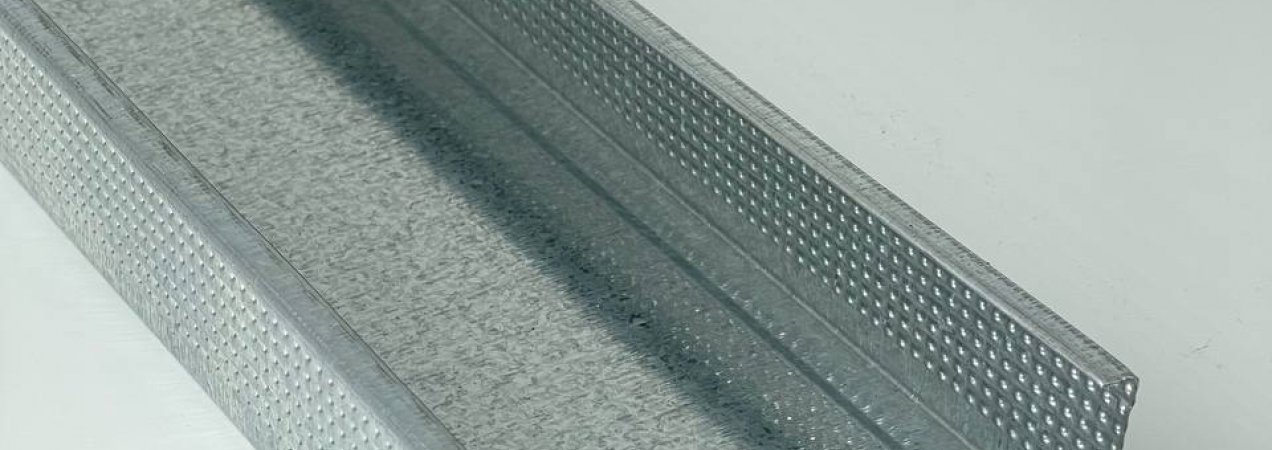

Perforated Corner Profile

Perforated corner profiles are frequently used in various areas and are an essential component in the construction sector. They come in different types, which can be selected according to specific needs, ensuring the right solution for each application.

Perforated corner profiles are typically used on surfaces such as concrete, aerated concrete, or brick in interior spaces. These profiles, which can be applied using machines or by hand, have a highly durable structure. They make it much easier to create sharp corners, which is why they are often preferred. This product is generally chosen for aluminum corners as well. With corner profiles, partition wall systems can be constructed, and they help ensure that corners have a cleaner and more uniform appearance. In addition, perforated corner profiles provide protection against impacts and damage. It is important to consider certain factors regarding the application area when using perforated corner profiles.

Common usage areas of perforated corner profiles include:

-

External corners in partition wall systems

-

External corners in suspended ceiling systems

-

External corners in wall cladding systems

In terms of dimensions and size, selection can be made according to the application area. There are no strict standard requirements for dimensions, and they can be customized to meet specific needs.

Rollform Lines

Rollform Lines

Rollform lines are systems designed to bend coil sheets and execute forming steps with precision,

ensuring the bending process progresses smoothly. Working on coil sheets can be challenging due to their

shaping difficulty and the effort required. With machines known as Roll Form, these processes

become much easier, reducing manual labor and delivering significant time savings.

What Are Rollform Lines?

When we look into Rollform lines, we see they play a crucial role in industry. They enable the

production of multiple profile cross-sections with ease. These functional machines allow coil sheets to be

uncoiled and formed to the required dimensions and specifications using appropriate methods.

Functions of a Rollform Line

- Forming pre-punched or pre-processed sheets

- Shaping punched or processed sheets after roll forming

- Easily creating intermediate bends

- Shaping cut material without scrap requirements

- Integrating processes such as welding, cut-to-length, and punching within the same line

Thanks to these features, Rollform lines are widely used across industrial sectors, offering

efficiency, precision, and flexibility in production.

U/C Profile

U/C Profile

In the industrial sector, U/C profiles are widely used and highly functional structural elements

with versatile application possibilities. They enhance the quality and functionality of the materials they are

used with. Thanks to the advantages and conveniences they provide, they are among the preferred structural

components in various projects.

The most common usage area is in partition walls. U and C profiles are used in different applications depending

on needs and requirements. They are named according to the bending and shaping of sheets produced with

rollforming technology.

U/C profiles are preferred both in the construction sector and in manufacturing. In addition to

wall partitions, they are also used in beams, especially in stair beams. Examples of usage areas include:

- Used in wall beams

- Found in beams under staircases

- Used in protective areas along wall edges

- Applied in ceilings

- Used in machine areas to separate frames or create a decorative look

U/C profiles use a back-to-back assembly method, enabling them to function as columns or beams. They come in

various sizes and dimensions to suit different sectors and applications. The most common industries where

U/C profiles are used include construction, industrial equipment and structures, metal manufacturing, steel

structures, building supports, and the automotive sector.

In gypsum board partition walls, U/C profiles provide excellent flexibility, increasing resistance

to dynamic forces. Compared to brick walls, they are approximately nine times lighter, which helps improve

building flexibility during natural disasters like earthquakes, reducing risks. They also ensure perfect

compatibility with gypsum board partitions, providing excellent sound, heat, and fire insulation.

Advantages of U/C Profiles

- Quick and practical installation

- Reduces labor costs due to fast and easy application

- Saves both time and money

- Prevents space loss in structures thanks to gypsum board partitions

Press Brake and Guillotine Shears

Press brake and guillotine shears are capable of working with small metal parts in a fast and efficient manner. They feature a first-class hydraulic system, foot pedal, pressure switch, PLC touch screen, and hardened and ground lower and upper table standards.

The application areas of press brake and guillotine shears are quite extensive. Examples include industrial kitchens, white goods, metal shelving, medical parts, fire extinguishing equipment, the construction industry, and many more. Optical barriers are available as optional features.

As with almost all electronic systems, malfunctions may occur in press brakes and guillotine shears and their components. These issues can be diagnosed and resolved using technical methods.

Press brake and guillotine shears are part of Cemax Engineering’s product range and are designed to deliver high quality service and reliable performance.

Guillotine Shear

Reducer-driven guillotine shears have a wide range of features, which can be categorized as standard equipment and optional features.

Among the standard features are: reducer drive system, cooled brake system, adjustable upper table guides, digitally controlled motor, back gauge system, high-alloy tool holder, blades providing four different cutting options, easily adjustable blade clearance, mechanical clamping system, angled front square and straight cutting capability, front finger protection barrier, emergency stop button, cutting line illumination, electrical system, and cutting line sensor.

In addition to these, optional features include angled sheet metal cutting, sheet metal lifting system, and safety barriers. These machines are widely preferred for their ability to simplify operations and improve efficiency.

Hydraulic Press Brake

Compared to other press types, hydraulic press brakes apply greater force, enabling the processing of denser materials. However, as the applied force increases, so does the risk. Therefore, as the potential hazards grow, every necessary occupational health and safety measure must be taken. Only after ensuring all safety protocols should the hydraulic press brake be put into operation.

The processed parts should be shaped using either a standard press or a hydraulic press, depending on the required force. Regardless of the choice, the most important priority is to ensure occupational safety, and the operation must always be carried out by skilled and experienced professionals.

Hydraulic press brakes have various features that make them suitable for specific usage purposes and processing needs. Some of the standard technical features include: proportional precision hydraulic system, adjustable valve system, remote control capability, emergency stop and restart function, hardened and ground upper dies, lower die with V-channel, control unit with graphic LCD screen, multiple language options, multi-memory function, programmable bending and angle settings, and an automatic calibration system that allows for consecutive precise bends. These capabilities make hydraulic press brakes a highly functional and efficient choice in metal forming operations.

Our Products

Our Products