Automatic Drywall Profile Production Line

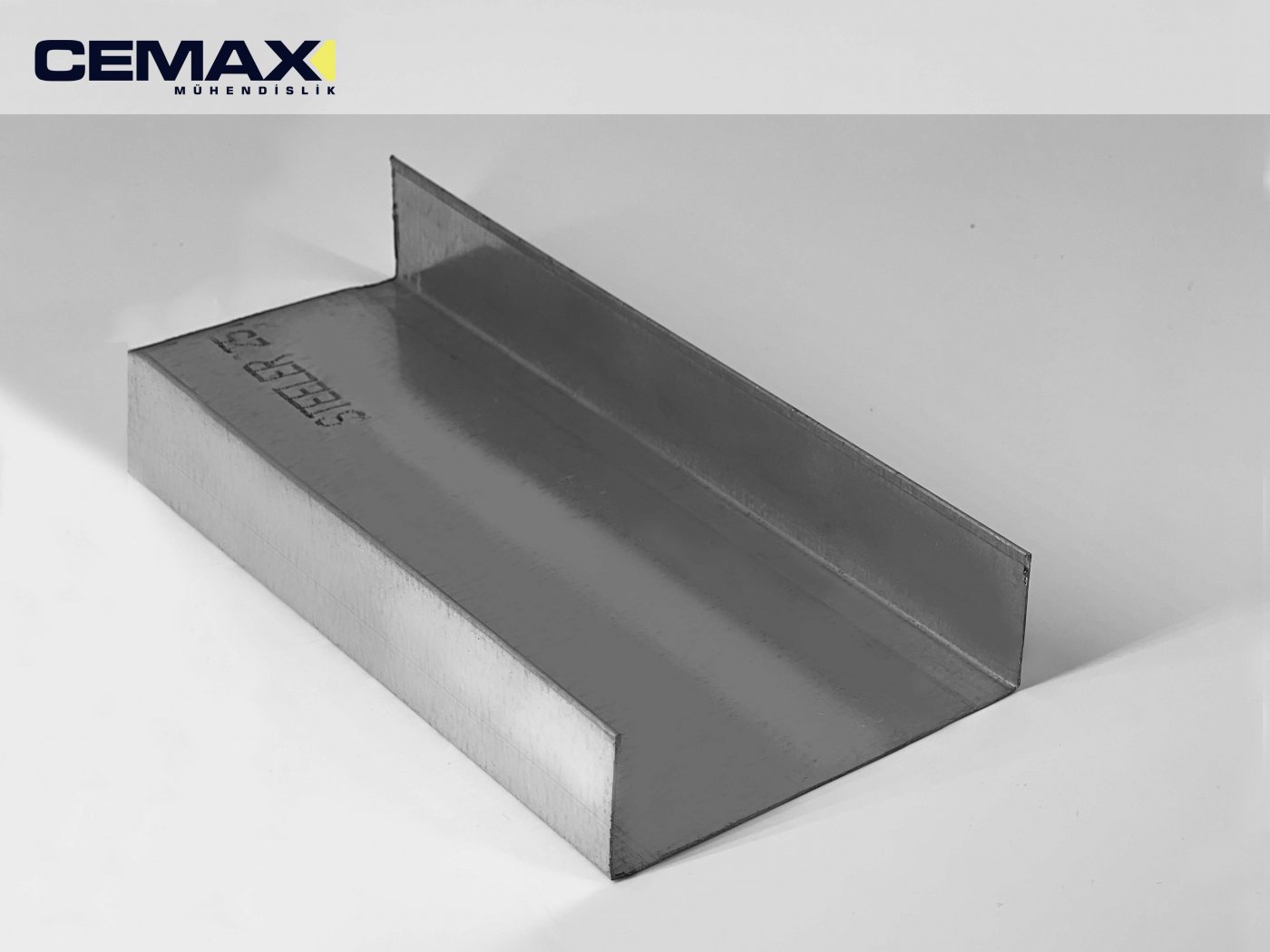

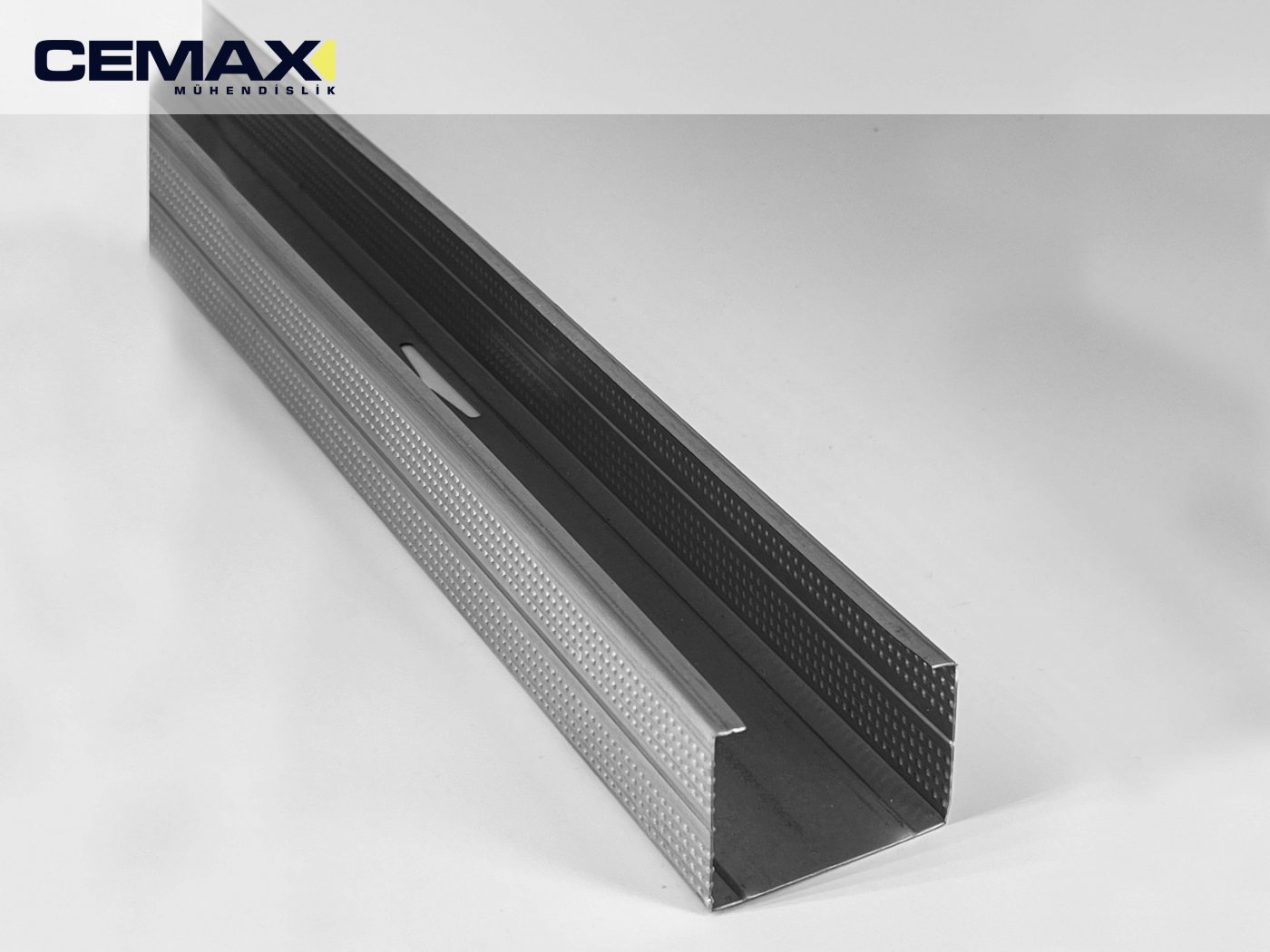

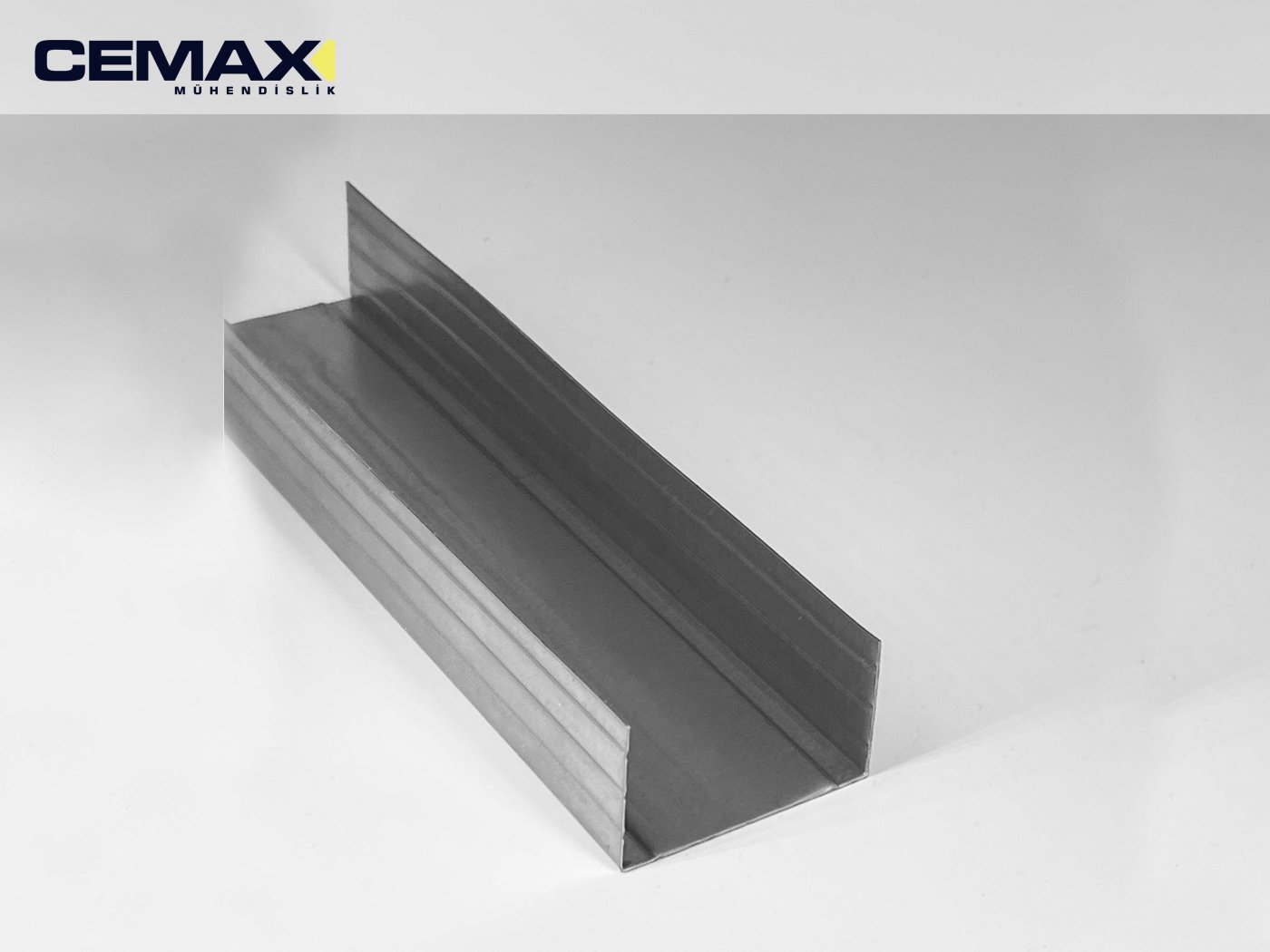

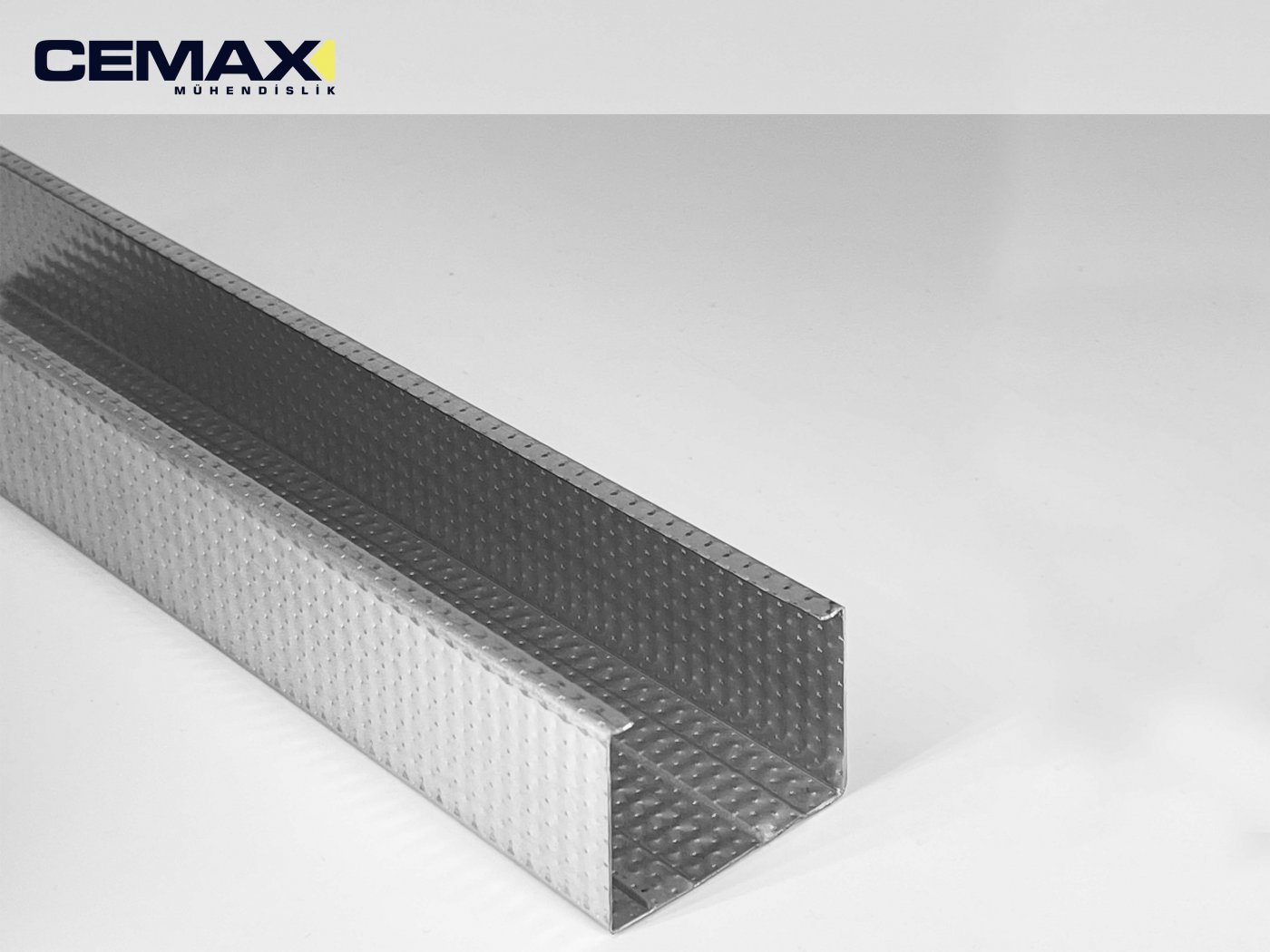

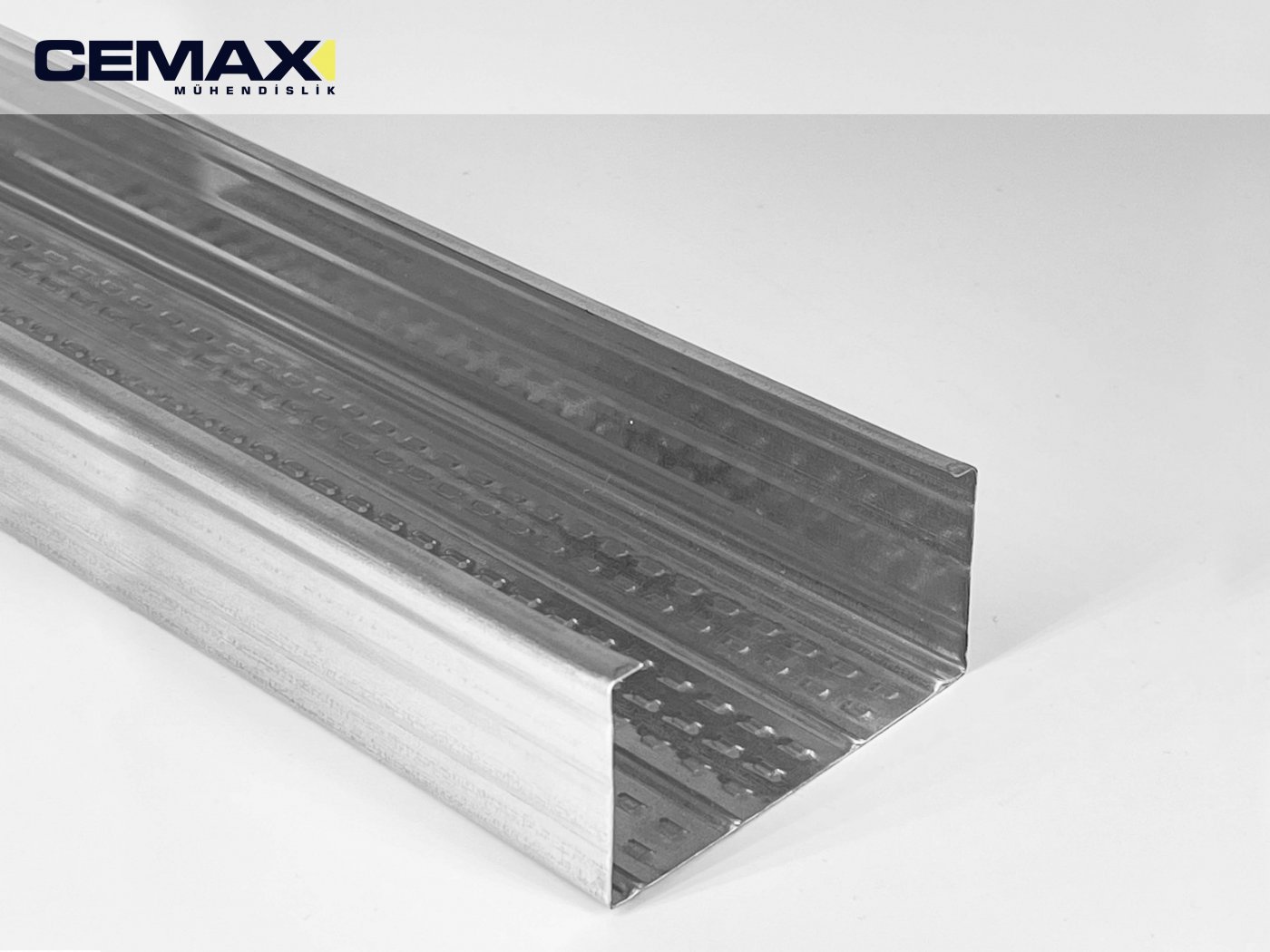

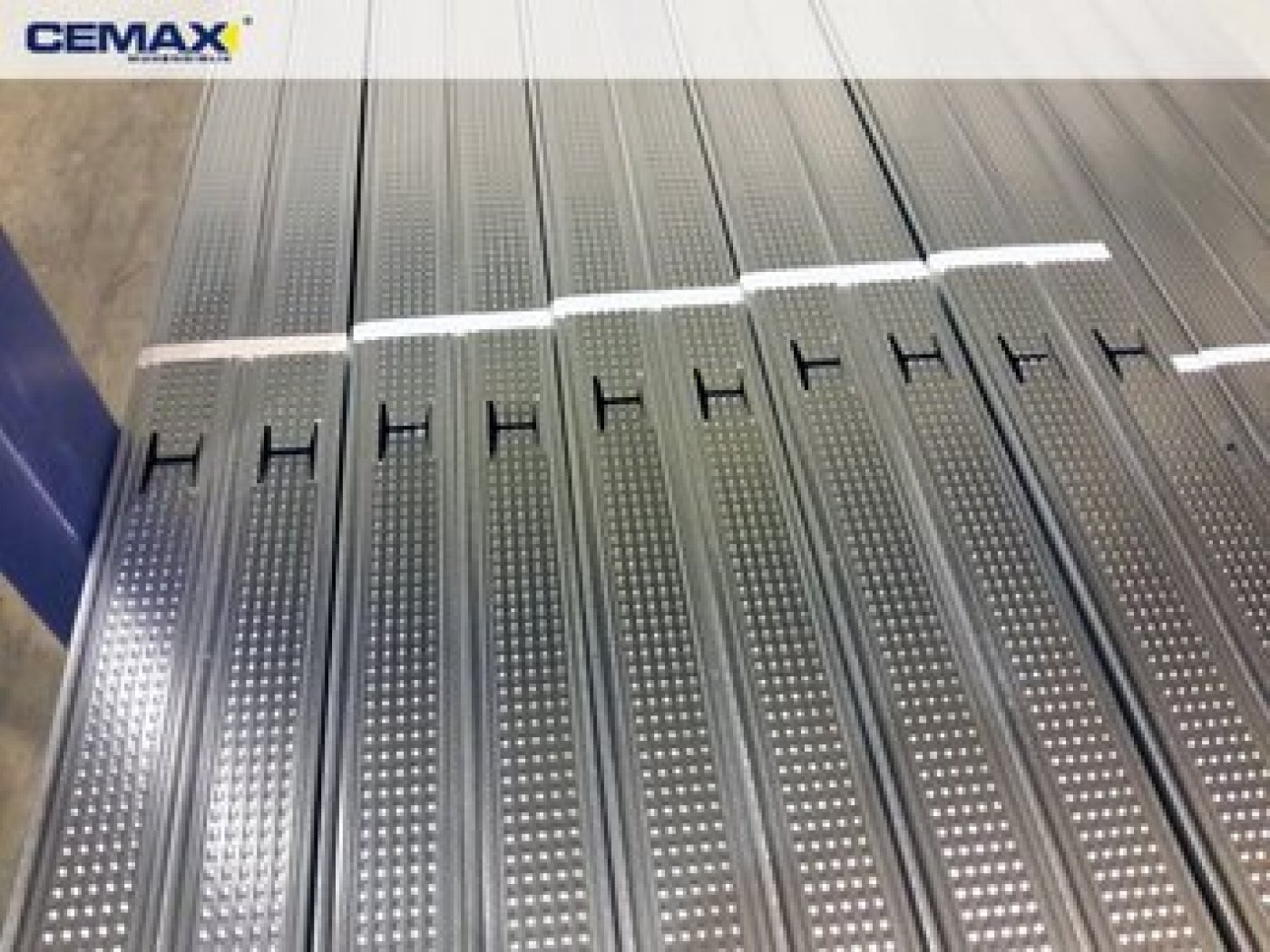

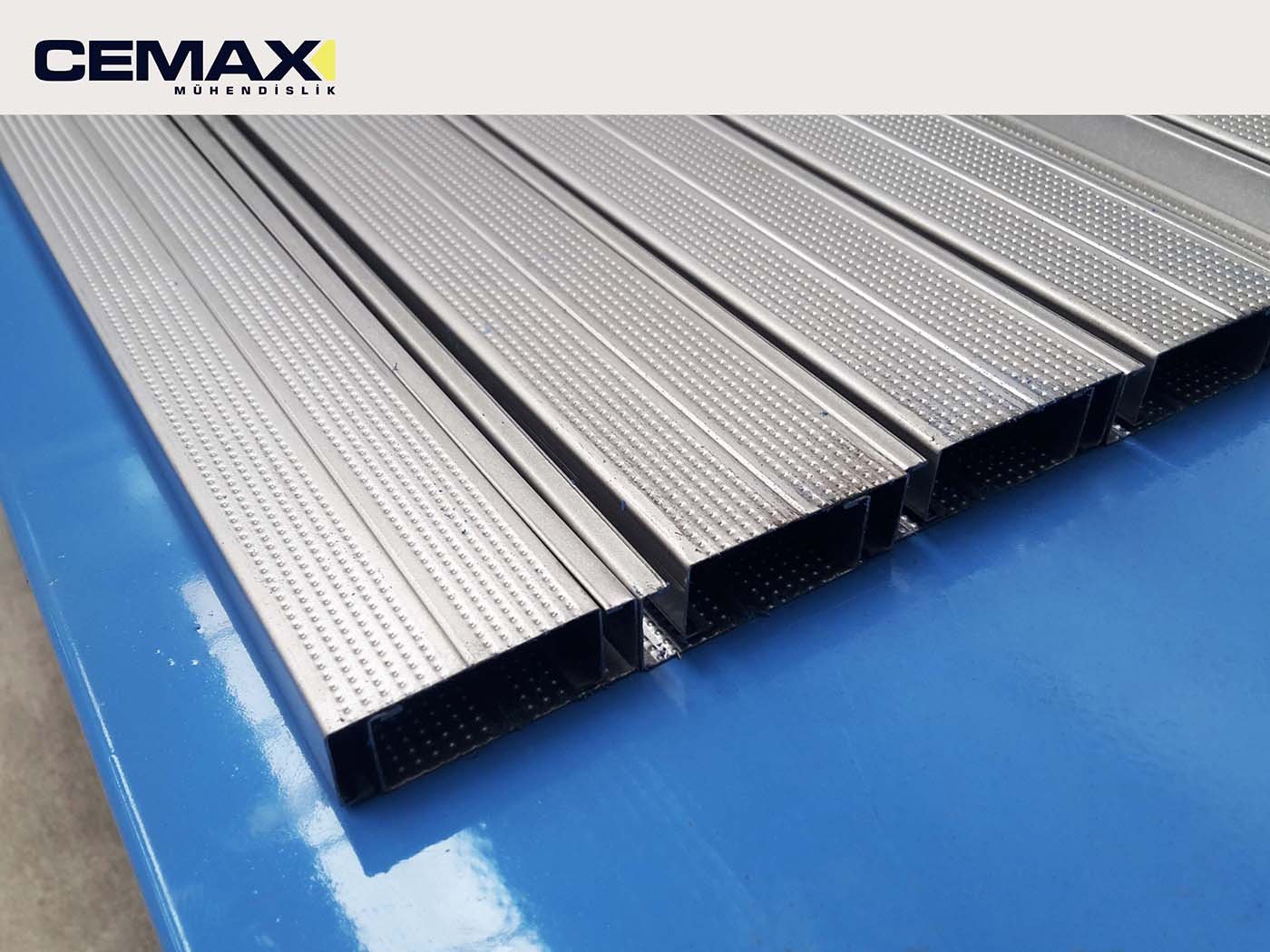

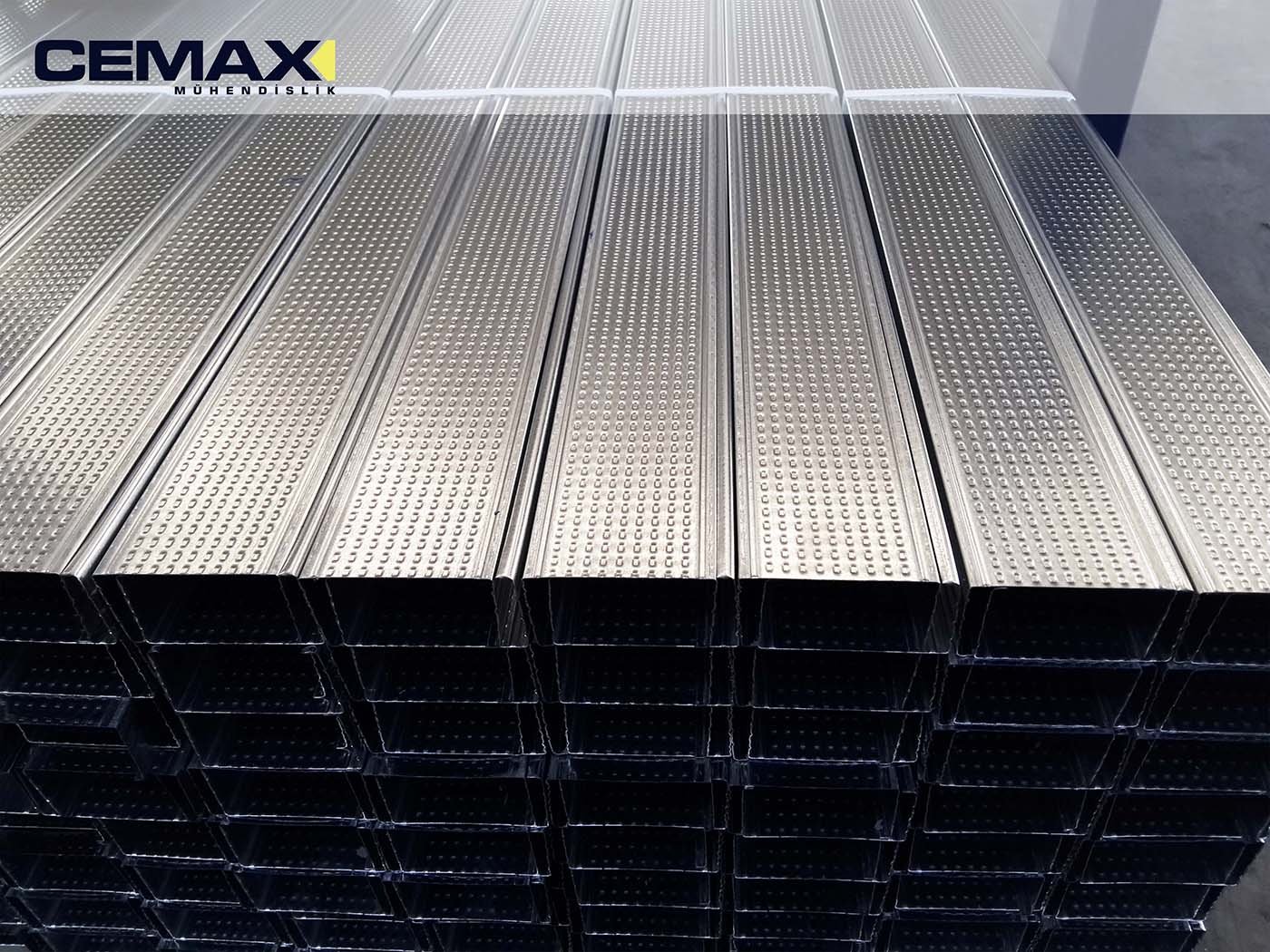

The automatic drywall profile production line is used to produce profiles with numerous applications, such as in insulation systems, partition wall construction, wall and ceiling cladding, wall lining or suspended ceilings, prefabricated building production, roofing and warehouse covering, as well as in stores and offices. These versatile profiles are essential in many construction and interior projects.

- Easy Installation

- Cost-Effective

- High-Strength Material

Production Line Videos

Drywall Profile Production Line

| Production Line Code | Production Line Equipment | Profiles That Can Be Produced | Number of Stations | Product Thickness Range | Production Line Speed |

|---|---|---|---|---|---|

| CMX-OTM1-PLUS | Decoiler – Rollform – Flying Shear – Profile Stacking Table | DU-DC | 14 Stations | 0.3 mm – 0.6 mm | 80 m/min |

Note: Equipment may vary depending on the profile you want to produce or your specific requirements.

| OPTIONAL EQUIPMENT | ||||

|---|---|---|---|---|

| Decoiler | Intermediate Tunnel | Press | Rollform | Flying Shear |

| Changeable Mandrel Count | Tunnel Width | Press Capacity | Number of Stations | Servo System |

| Changeable Weight Capacity | Tunnel Height | Servo Drive System | Cassette/Non-Cassette System | Pneumatic System |

| Changeable Coil Clamping System | Branded/Unbranded System | Angled Cutting – Scrap Cutting System | ||

| Add-on Sheet Feeding System | ||||

Our Products

Our Products