Container and Prefabricated Production Line

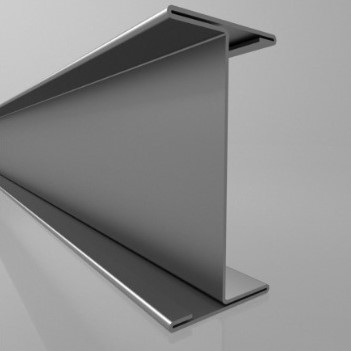

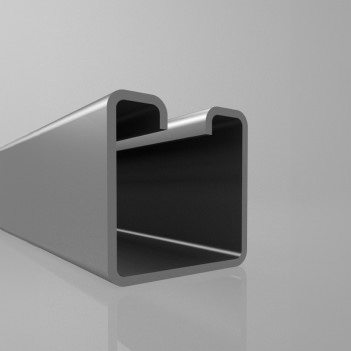

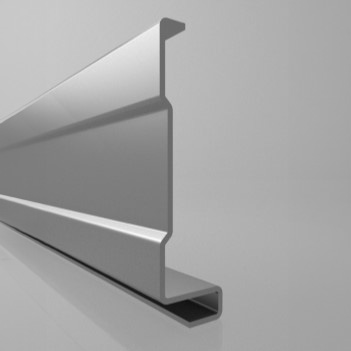

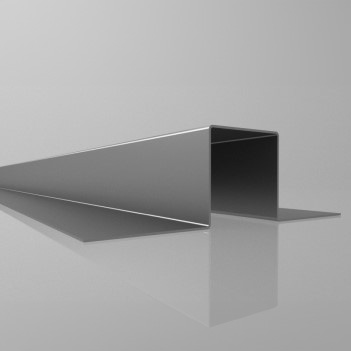

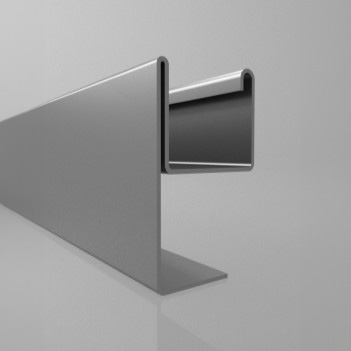

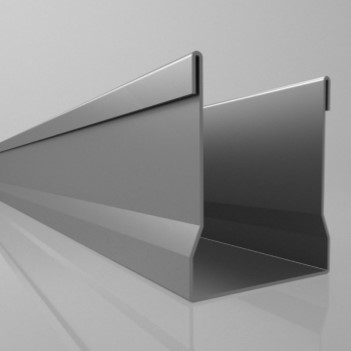

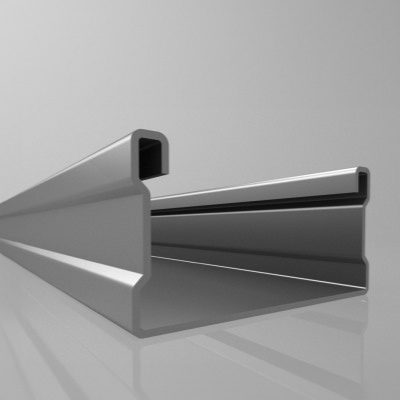

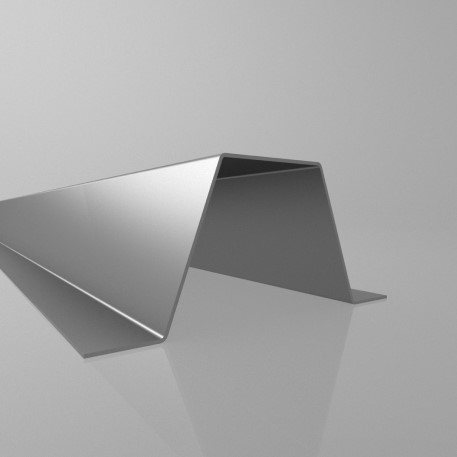

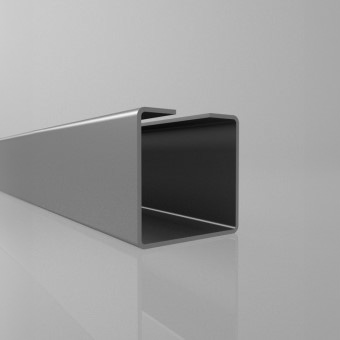

Container chassis profiles form the foundation of the structural integrity and durability of containers. Container Modular manufactures high-quality chassis profiles, ensuring the safe and long-lasting use of containers.

- Easy Installation

- Cost-Effective

- High-Strength Material

PRODUCTION LINE CODE: CMX-PRF1-PLUS

| COIL UNWINDING | |

| *Carrying Capacity | 2,000 kg |

| *Coil Width | 350 mm |

| *Coil Diameter | 1300 mm |

| *Clamping System | Manual Clamping |

| *Base Connection | Sliding Stand, Left-Right Movement |

| *Mandrel Closed and Open Size | 450-550 mm |

| *Operating System | With Brake |

| ROLLFORM | |

| *Number of Stations Machine-1 | Single station |

| *Shaft Diameter / Length | 50 mm / Length adjustable to fit max. 350 mm strip |

| *Roller Group | Made of Ç4140 material, hardened to 56/58 HRC |

| *Gear Group | Made of Ç8620 material, bearing diameters ground after heat treatment |

| *Bearings | FAG, SKF, ORS or equivalent used |

| *Gearbox | Brand: Yılmaz |

| *Sheet Thickness | Can draw galvanized metal with thickness of 0.7 – 1.0 mm and 0.8 – 1.2 mm. Can profile both unpainted and painted galvanized metal. |

| *Die change from 60 to 100 | Magnetic bushings made for two sizes of the same profile, change without removing stands. |

| AUTOMATION | |

| *Servo Equipment | Brand: Omron |

| *Motor Drivers | Brand: Omron |

| *Switchgear | Brand: Siemens, Moller |

| LENGTH CUTTING AND CABLE HOLE PRESS | |

| *Motion Mechanism | Hydraulically operated length cutting with 10-ton pressing capacity. |

| *Length Cutting Die | Made of 2379 tool steel, heat-treated to 58-60 HRC and ground. |

| *Hole Punching Die | Made of 2379 tool steel, heat-treated to 58-60 HRC and ground. |

Our Products

Our Products