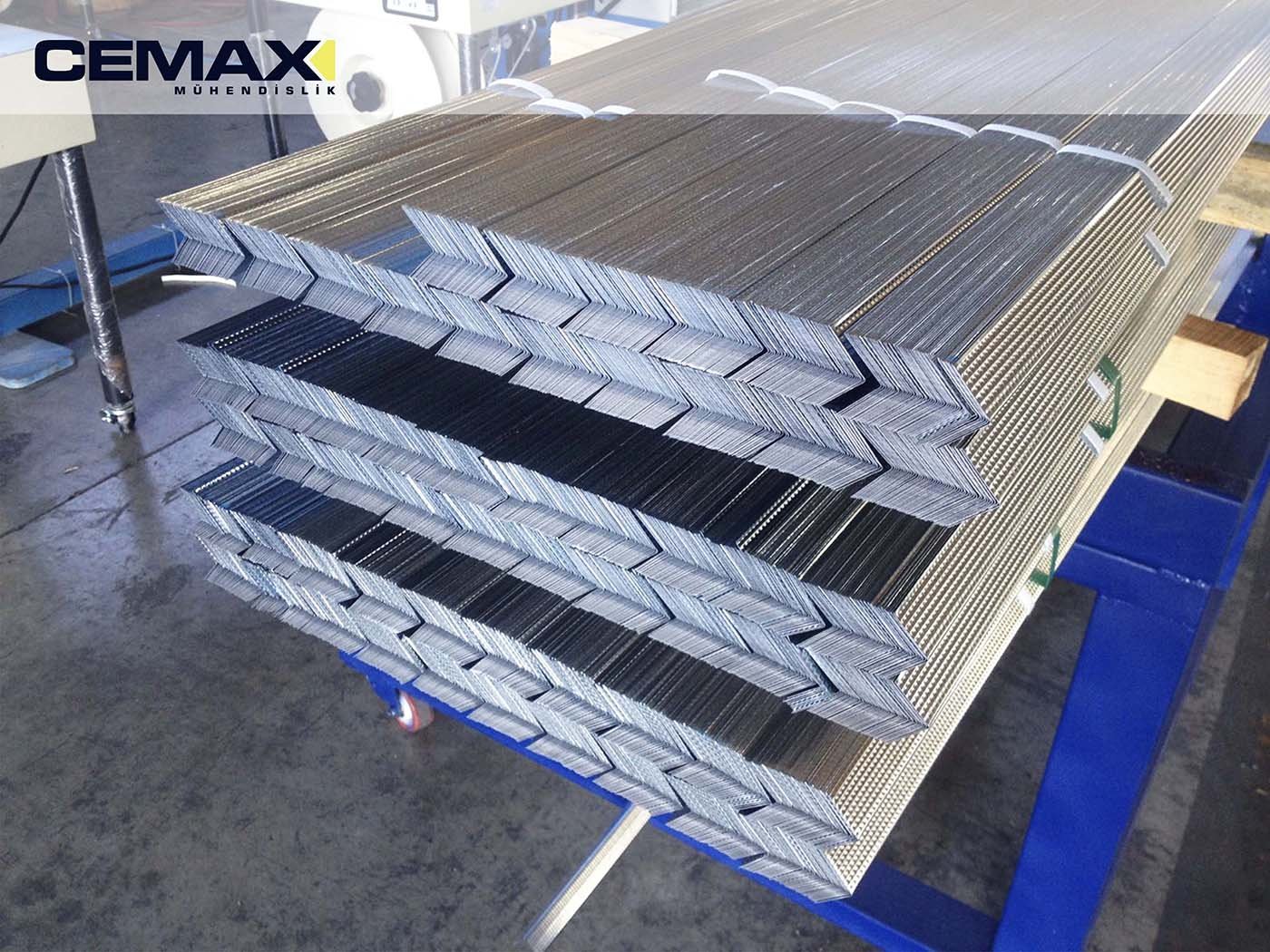

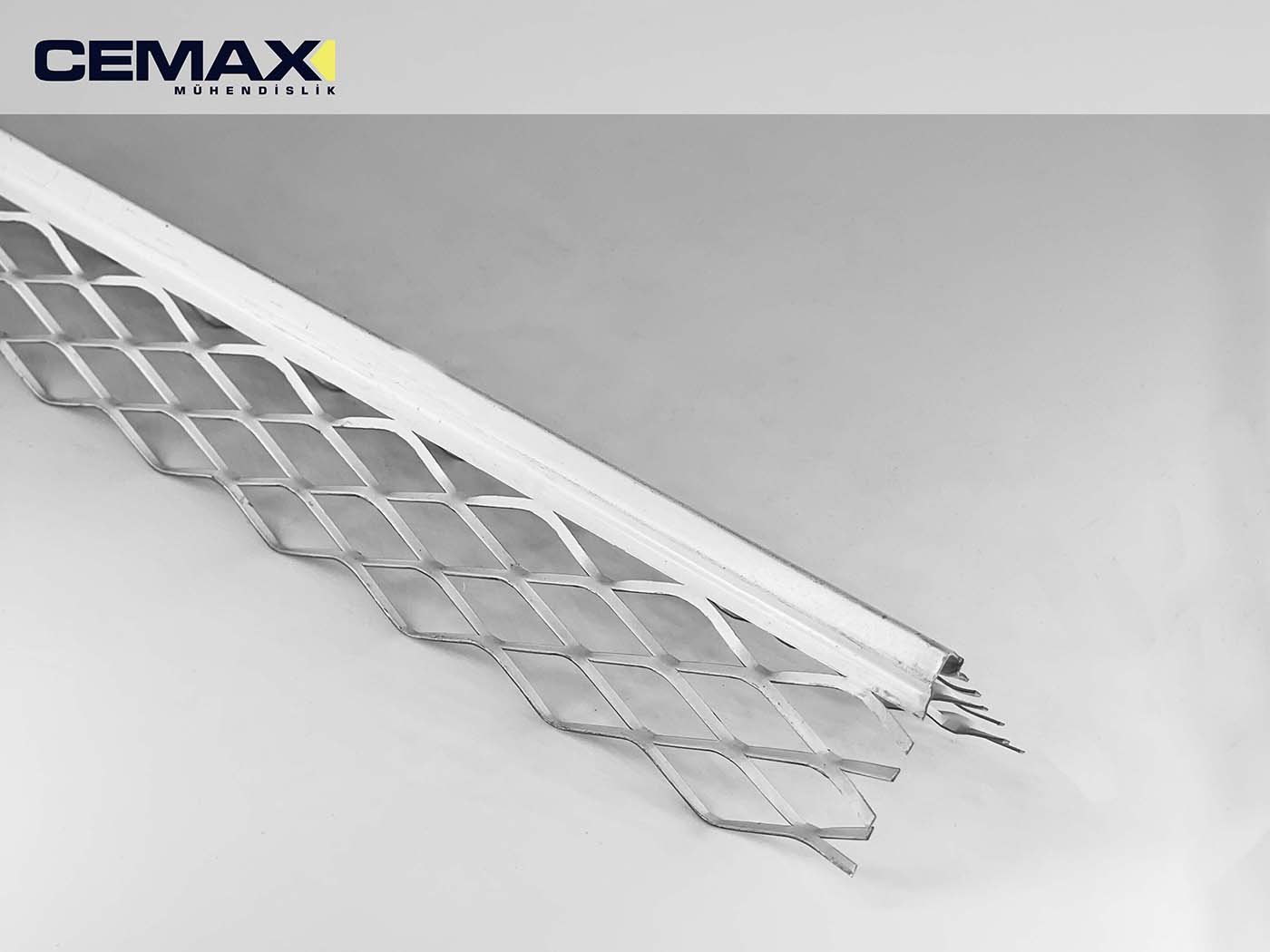

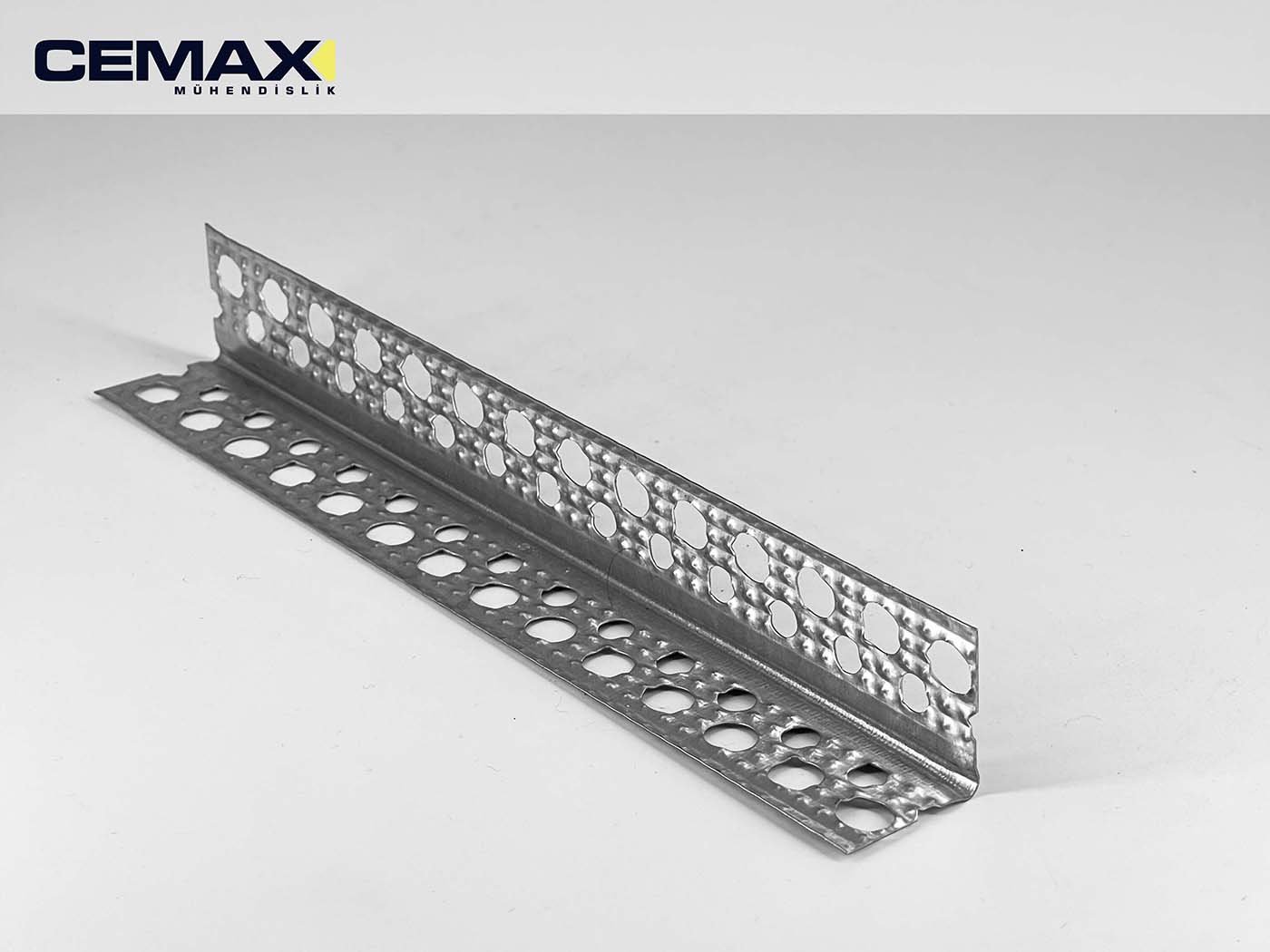

Corner Profile Production Line

These are production lines that manufacture profiles made from galvanized sheet metal, used in gypsum board systems to protect external corners against impacts and to create a clean, precise corner detail.

- Easy Installation

- Cost-Effective

- High-Strength Material

Production Line Videos

| Production Line Code | Product Description | Profiles That Can Be Produced | Number of Stations | Technical Specifications | Product Thickness to be Drawn | Production Line Speed |

|---|---|---|---|---|---|---|

| CMX-KPH1-PLUS | Plaster Corner Profile Production Line | Plaster Corner Profile | 6 stations | Decoiler – Intermediate Tunnel – Eccentric Press – Intermediate Tunnel – Rollform – Length Cutting – Stacking Table | 0.3 mm – 0.5 mm | 30 m/min – 50 m/min |

| CMX-KPH2-PLUS | Plaster Corner Profile Production Line | Gypsum Corner Profile | 6 stations | Decoiler – Intermediate Tunnel – Eccentric Press – Intermediate Tunnel – Rollform – Length Cutting – Stacking Table | 0.3 mm – 0.5 mm | 30 m/min – 50 m/min |

| CMX-KPH3-PLUS | Plaster Corner Profile Production Line | Plaster Guide Profile | 8 stations | Decoiler – Intermediate Tunnel – Eccentric Press – Intermediate Tunnel – Rollform – Length Cutting – Stacking Table | 0.3 mm – 0.5 mm | 30 m/min – 50 m/min |

| CMX-KPH4-PLUS | Plaster Corner Profile Production Line | Gypsum Corner Profile | 6 stations | Decoiler – Intermediate Tunnel – Eccentric Press – Intermediate Tunnel – Rollform – Length Cutting – Stacking Table | 0.3 mm – 0.5 mm | 85 m/min |

| CMX-KPH5-PLUS | Gypsum Corner Profile Production Line | Plaster Guide Profile | 6 stations | Decoiler – Intermediate Tunnel – Eccentric Press – Intermediate Tunnel – Rollform – Length Cutting – Stacking Table | 0.3 mm – 0.5 mm | 85 m/min |

| Optional Equipment | ||||

|---|---|---|---|---|

| Decoiler | Intermediate Tunnel | Press | Rollform | Flying Shear |

| Changeable Head Quantity | Tunnel Width | Press Capacity | Number of Stations | Servo System |

| Changeable Weight Capacity | Tunnel Height | Servo Drive System | Cassette/Non-Cassette System | Pneumatic System |

| Changeable Coil Clamping System | Branded/Unbranded System | Angled Cutting – Cutting with Scrap System | ||

| Addable Sheet Feeding System | ||||

Our Products

Our Products