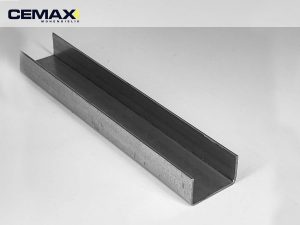

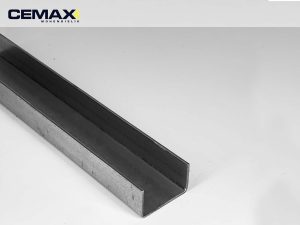

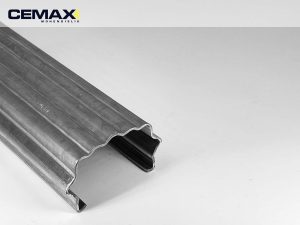

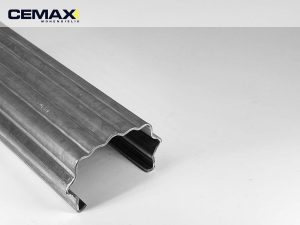

Rollform lines have a structure that enables the bending and steps of the rolled sheets and the advantage of being able to advance the bending processes smoothly. Since the operations to be performed on the roll sheets are in a structure that is difficult to shape, they are in a structure that requires a lot of strength and can be difficult to shape. Thanks to the machines called Rollform, this process becomes much easier and thanks to these machines, the use of manpower is less and it can become very useful in terms of time saving.

What are Rollform Lines?

When we are wondering about Rollform lines, we can go on a quest and want to get information about Rollform lines. Rollform Lines, which are very important in the field of industry, have a functional structure. It is possible to produce a large number of profile sections with Rollform lines that can be made much more easily. The machine, which is used in the industrial sector and is functional in meeting the needs on the basis of the sector, makes it possible to open the sheet in rolls with a suitable method and to bend it in an appropriate size and structure.

What are the Rollform Line Functions?

We can talk about the functional features of the Rollform line, which has a very functional structure;

Sheet that has been pierced and played on can be styled.

After Rollform styling, pierced or processed sheet can be shaped.

The forming of intermediate bends can be done easily.

It can be shaped without the need for wastage of the cut material.

It is possible to perform process groups such as welding, length cutting, hole drilling in the Rollform Line.

The Rollform functions we have listed are among the reasons for preference due to the benefits it provides in the field of industry. And it is used by companies in the sector.