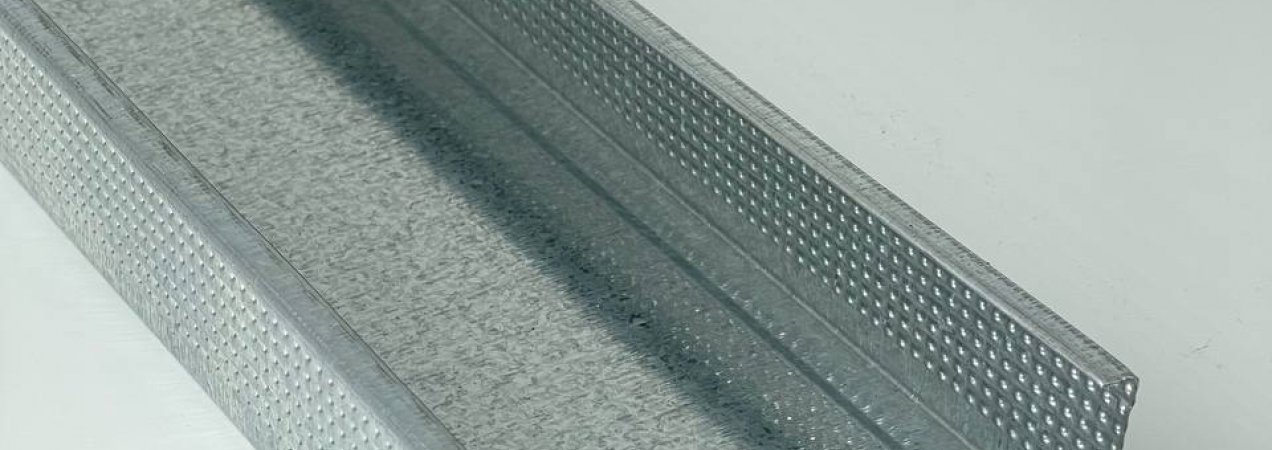

Perforated Corner Profile

Perforated corner profiles are frequently used in various areas and are an essential component in the construction sector. They come in different types, which can be selected according to specific needs, ensuring the right solution for each application.

Perforated corner profiles are typically used on surfaces such as concrete, aerated concrete, or brick in interior spaces. These profiles, which can be applied using machines or by hand, have a highly durable structure. They make it much easier to create sharp corners, which is why they are often preferred. This product is generally chosen for aluminum corners as well. With corner profiles, partition wall systems can be constructed, and they help ensure that corners have a cleaner and more uniform appearance. In addition, perforated corner profiles provide protection against impacts and damage. It is important to consider certain factors regarding the application area when using perforated corner profiles.

Common usage areas of perforated corner profiles include:

-

External corners in partition wall systems

-

External corners in suspended ceiling systems

-

External corners in wall cladding systems

In terms of dimensions and size, selection can be made according to the application area. There are no strict standard requirements for dimensions, and they can be customized to meet specific needs.

Similar Posts

Gypsum Board Profile Production Lines

In the construction sector, the demand and need for gypsum board is increasing day by day. Rapidly advancing technology, when...

Rollform Lines

Rollform Lines Rollform lines are systems designed to bend coil sheets and execute forming steps with precision, ensuring the bending...

U/C Profile

U/C Profile In the industrial sector, U/C profiles are widely used and highly functional structural elements with versatile application possibilities....

Our Products

Our Products