Rollform Lines

Rollform Lines

Rollform lines are systems designed to bend coil sheets and execute forming steps with precision,

ensuring the bending process progresses smoothly. Working on coil sheets can be challenging due to their

shaping difficulty and the effort required. With machines known as Roll Form, these processes

become much easier, reducing manual labor and delivering significant time savings.

What Are Rollform Lines?

When we look into Rollform lines, we see they play a crucial role in industry. They enable the

production of multiple profile cross-sections with ease. These functional machines allow coil sheets to be

uncoiled and formed to the required dimensions and specifications using appropriate methods.

Functions of a Rollform Line

- Forming pre-punched or pre-processed sheets

- Shaping punched or processed sheets after roll forming

- Easily creating intermediate bends

- Shaping cut material without scrap requirements

- Integrating processes such as welding, cut-to-length, and punching within the same line

Thanks to these features, Rollform lines are widely used across industrial sectors, offering

efficiency, precision, and flexibility in production.

Similar Posts

Gypsum Board Profile Production Lines

In the construction sector, the demand and need for gypsum board is increasing day by day. Rapidly advancing technology, when...

Perforated Corner Profile

Perforated corner profiles are frequently used in various areas and are an essential component in the construction sector. They come...

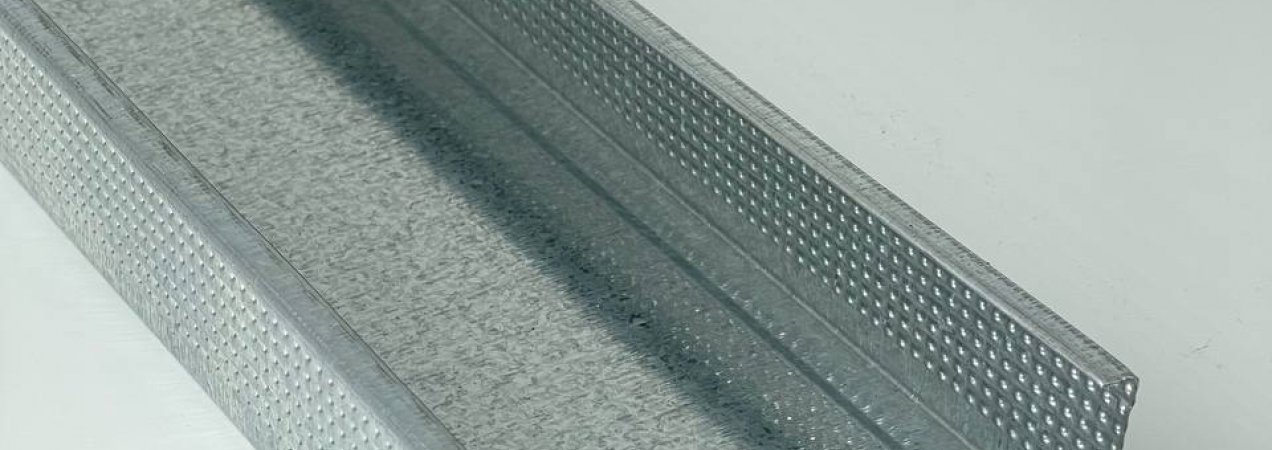

U/C Profile

U/C Profile In the industrial sector, U/C profiles are widely used and highly functional structural elements with versatile application possibilities....

Our Products

Our Products